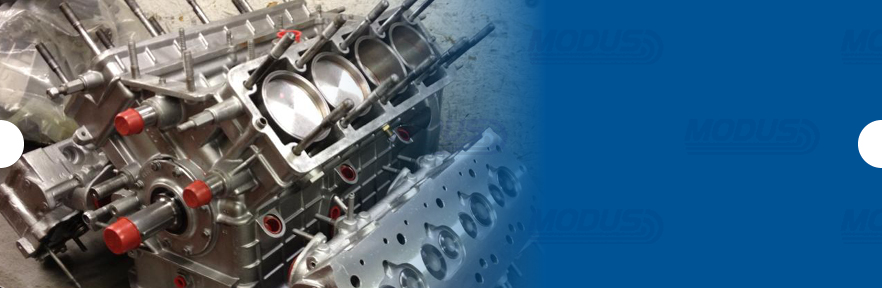

Cylinder heads

Whether you just require a pressure test and skim or full remanufacture following a timing failure we can help by offering a full range of services.

We will assess the level of damage to your cylinder head first by pressure testing it then by performing a vacuum test to check the quality of seal between valve and seat. The cylinder head face will then be checked for distortion and the valves removed to check for valve guide wear and valve damage.

The condition of the camshaft, cam housings, cam followers and their respective bores will also be checked.

Cylinder head pressure testing

Modus operates a Serdi hot pressure testing facility which submerges the cylinder head in very hot water. This offers a quick and inexpensive method of checking that the cylinder head casting is sound and there are no cracks present or other breaches of the cooling system. The pressure test is done hot to simulate the operating temperature of the engine.

Modus can also pressure test cylinder blocks, turbos, EGR valves and oil coolers.

Cylinder head remanufacture

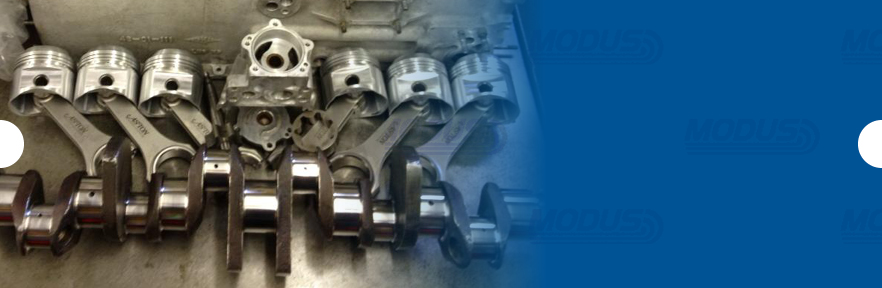

All our remanufactured cylinder heads go through a very stringent process. They are first stripped and hot presssure tested, once passed all core plugs and oil gallery plugs are removed and they submerged in a cleaning tank to remove all traces of paint, oil, grease and carbon.The valves are bead blasted and then brushed, the seating angle and tip of the valve are remachined and the stem and head polished. All valve guides are sleeved using a hard wearing bronze liner and the valve seats are cut with a 3 angle form tool.

The cylinder head face is surface ground if cast iron or fly cut with a diamond PCD cutter if aluminium and a final clean performed before assembly with new core plugs and oil gallery plugs fitted.

In the case of cylinder heads with hydraulic lifters, these are stripped, cleaned and checked before being rebuilt. If the cylinder head has solid lifters the valve clearances are reset to the manufacturers specification.