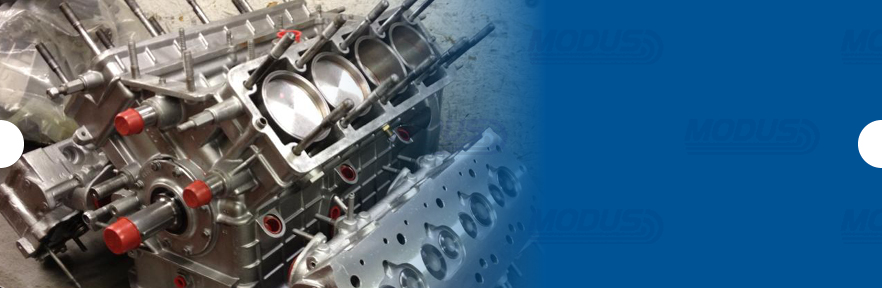

Cylinder blocks

Prior to any machining all cylinder blocks have their core plugs and oil gallery plugs removed and are submerged in a cleaning tank to remove old paint and all traces of oil & grease. Once clean the cylinder block is inspected for any defects including bore wear or damage, crankshaft housing wear or damage and cam bearing wear. Cylinder blocks can also be hot pressure tested if required.

New cam bearings can be fitted and the cylinder block face skimmed.

After the machining processes are finished a final clean is carried out including using specialist brushes throughout the oil galleries. The cylinder block is then painted and new core plugs and oil gallery plugs are installed.

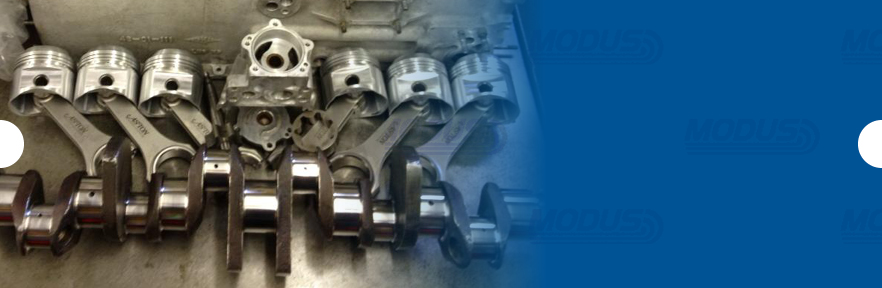

Reboring and sleeving

Cylinder blocks can be rebored and new pistons supplied if they are tired or sleeved back to standard if badly damaged or bored out before.

Modus can rebore anything from a moped to large industrial applications, sizes range from 30 mm to 200 mm

Honing

Honing is one of the most important processes in engine remanufacture. It is vital that correct technique is used to acquire the right depth and angle of pattern to the finished bore to give miles of oil burning free service.

Modus uses a Delapena H276 auto stroker (it sounds impressive !) its quite an old machine but its very effective. We bore to within .005″ of the finished size then hone .002″ with a coarse diamond followed by the last .003″ with a silicon carbide stone. The bore is then plateau finished with compressed cork, this part is imperative for preventing oil burning.